Hot-selling NDSM21/42E direct purpose warping machine

“Quality to start with, Honesty as base, Sincere company and mutual profit” is our idea, as a way to build constantly and pursue the excellence for Hot-selling NDSM21/42E direct purpose warping machine, We welcome new and old shoppers from all walks of life to contact us for long run enterprise relationships and mutual accomplishment!

“Quality to start with, Honesty as base, Sincere company and mutual profit” is our idea, as a way to build constantly and pursue the excellence for , Profession, Devoting are always fundamental to our mission. We’ve got always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

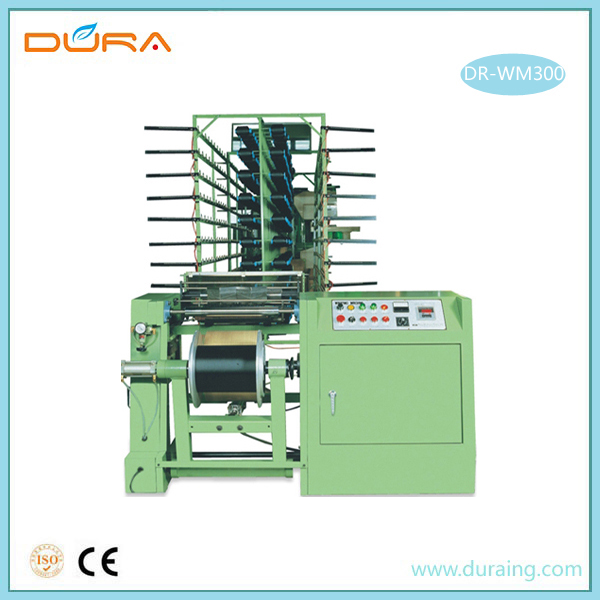

WM300 Warping Machine

The yarn warping machine is applicable to each kind of yarn. Warping can be effected on one of beams at a time special attachments guarantee a perfect uniformity of tension of all ends from the beginning to the end of the warping operation.

In fact, the warping angle is held constant and the pressure between the drive roller and the beam is brought about by a air pressure between the drive roller and the beam is brought about by a air pressure system, permitting a variation according to requirements.

A triphase motor provides the drive of the warper. By means of a friction drive the beam can steplessly be put into either forward or backward motion, in order to ease tying of ends.

The machine is equipped with an expansion reed the number of dents of which is determined according to customer’s requirements.

Application

For all kinds of yarn like nylon, polyester…etc

Features

- The warp yarn machine can be used to pass a variety of yarns, each time a pan head (BEAM) can be placed. This machine uses a DC motor to supply the horsepower transmission roller, which is driven by the friction between the superior rubber roller and the pan head. The friction can be adjusted as needed to achieve the desired requirements for the yarn on the pan head. This machine has special equipment to ensure that the tension is constant from the beginning of the warp to the completion of the warp. It saves yarn waste because it has a Length preset switch. Moreover, the steel shovel equipped with a retractable device can be easily adjusted to save time according to the required density; the automatic disconnection device is convenient for operation.

- Specially designed synchronous motor control system and fine-tuning system for control, the tension can be placed in any space without using the drive shaft.

- The steel buckle with the length setting device and the retractable device is adjusted according to the required length and density to easily arrange the glue wire, saving time and being easy to operate.

© Copyright - 2010-2019 : All Rights Reserved by Shanghai Dura Industrial Co., Ltd.

© Copyright - 2010-2019 : All Rights Reserved by Shanghai Dura Industrial Co., Ltd.