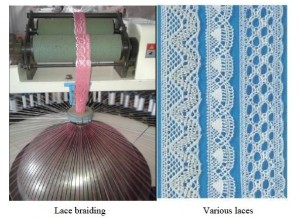

96 Spindle Computerized Lace Braiding Machine

I. Brief introduction

This new generation 96 spindle computerized lace braiding machine is designed and updated by our experienced technicians who have been working in this filed for more than 30 years. After more than ten-year’s practical production all over the world, this design has been the most mature technology and won the good reputation because of its compact size, stable performance, easy maintenance and long life-span etc.

II. Application

The computerized lace braiding machine has been widely used for producing various decorative laces with different materials for:

- High-grade dresses

- Shoes and hat

- Drawnwork table cloth

- Curtains

- Bedclothes

III. Advantages

- Completely automatic: the computerized control system can automatically read the lace pattern design, monitor the knitting process, accurately regulate the knitting speed, display and record the process sheet, discovery and display the faults etc.

- Automatic and accurate fabric count regulation: the fabric count can be freely regulated between 0.1-3 mm during the operation and the accuracy can reach 0.01mm to form special lace patterns.

- Wide range of lace pattern options: the computerized control cabinet has a record of more than 500 lace pattern designs. Our users can freely choose the design and produce the beautiful lace.

- High compatibility: the lace pattern design software is compatible with Germany and Japan’s software. So our lace braiding machine can read and produce almost all the lace patterns designed by Germany or Japan’s software.

- Wide application Various yarns can be applied in this lace braiding machine, such as pure cotton, hemp, silk and chemical fibre etc. And the fineness of yarns can reach 603,602,803 and 802 etc.

- Advanced safety protection: the whole machine can automatically shut-down triggered by yarn break, empty bobbins and overload safety clutch etc. The control panel will display the possible faults.

IV. Specification

| Item/Parameter/Code | DR-96 |

| Spindle Number | 96 |

| Gauge | 45-55 |

| Bobbin Size | Φ37×91 |

| Lace Width | 5-250 |

| Weaving Speed | 40-300 |

| Electrical Motor | 1.5kw/380VAC |

| Outsize Size(mm) | 2650x1750x1950 |

| Weight/kg | 1200 |

V. Installation, Guarantee and Documents

A. Documents

1) Operation manual

2) Electrical principle chart and instruments list

3) Spare parts list

B. Installation and after sales service

1) It is the seller’s responsibility to install, debug and train buyer’s operating personnel and the buyer should provide assistant, simple accommodation and the transportation fee for the seller’s technicians.

2) The trial-manufacturing in customer’s plant will last for 12 hours continuously after the debugging then the acceptance agreement will be signed by the two sides. The machine will be guaranteed for one year.

3) After the guarantee period, the sellers will supply maintain service for value and preferential parts.

4) The seller will regularly contact the user to record the machine’s performances.

C. Guarantee 12 moths

© Copyright - 2010-2019 : All Rights Reserved by Shanghai Dura Industrial Co., Ltd.

© Copyright - 2010-2019 : All Rights Reserved by Shanghai Dura Industrial Co., Ltd.